Machines

Gum Mixers

Our Double Z Arm Mixers are designed to deliver 300 kg and 500 kg capacity mixing performance, as well as reliability and durability. Mixing is carried out by two Z-arms located at the bottom of the pan, rotating in opposite directions and at different speeds, causing the product to move continuously from the side walls to the center of the kneading bowl or vice versa. Unloading of the mixed product can be accomplished by tilting the bowl or by means of a drain screw placed horizontally parallel to the Z-arms.

For detailed information about the machines, please contact us.

Extruderler

It is produced as a counter-rotating twin screw for processing chewing gum and confectionery masses. It is the perfect partner of extruders, ball formers, cutting and packaging machines with reliability, flexibility and high efficiency. The comprehensive and twin screw extruder is produced to meet your processing needs in the best way.

For detailed information about the machines, please contact us.

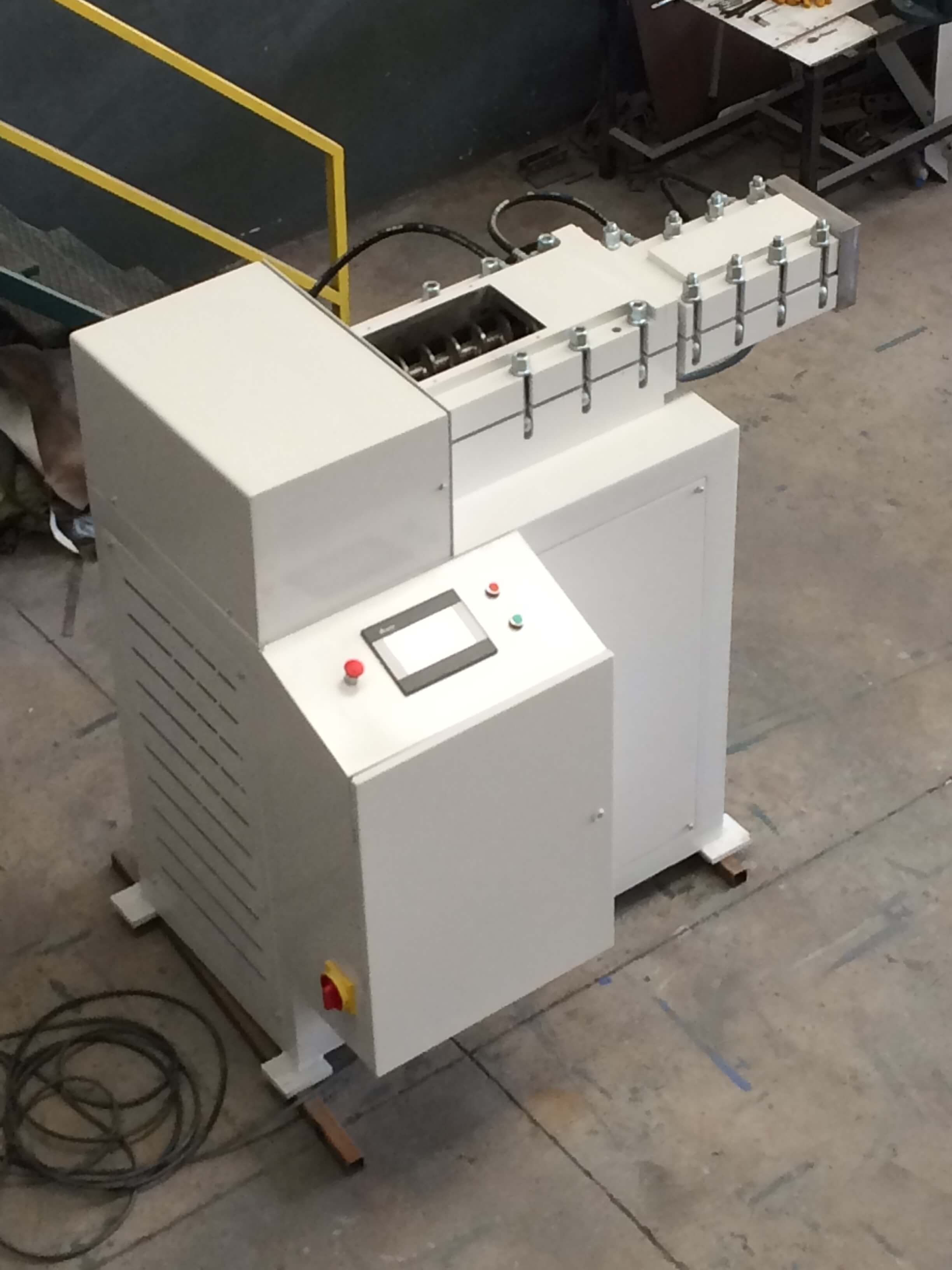

Ball Gum Shaping Units

Ball gum shapers are designed for the production of cylindrical hollow, filled and filled products of gum, bubble gum, soft candy, candy, fruit paste and similar masses. Optimized design and powerful performance together with increased precision ensure maximum efficiency. Thanks to its excellent user-friendliness and the ability to work with a wide variety of different masses, it meets the highest production and quality demands. Customizable forming, cutting system specially designed to prevent leakage when working with filled products are some of the machine features.

Candy Shaping Units

Sugar shaping machines are specifically designed for the production of solid and center-filled high quality sugar, offering durability and reliability as well as high capacity forming performance. Our machines are designed to withstand the rigors of high efficiency confectionery production. Sugar shaping is designed with strength and durability, as it is at the heart of the production line.

For detailed information about the machines, please contact us.

Cooling Tunnels and Units

Cooling tunnels are designed for high performance precision cooling while preserving the shape and quality of the original products produced. In the production of ball gum, the extra wide product layers are designed to allow the gums to roll continuously and thus prevent deformation. The optimized cooling airflow system provides high capacity, uniform and gentle cooling, and circulates cold air to quickly cool products from forming temperature to packaging temperature.

Since not every manufacturer has the same needs, our equipment can be configured with different options to meet the required capacity. In addition, our cooling tunnels can be upgraded to high capacity to provide a cost effective solution to your growing production needs.

Please contact us for detailed information.

Coating Drum

It can be used in a wide variety of coating and polishing processes. Its versatility and flexibility make coating drums particularly suitable for the confectionery and pharmaceutical industries. Coating drums are functional, easy to maintain, adaptable and manufactured to quality specifications to ensure years of trouble-free operation. Our models allow you to produce batches of 50, 80 and 100 Kg with high efficiency for ribbed or flat surfaces.

Please contact us for detailed information.

Pulling (Sugar Pull)

PullingIts machines are used for drawing and aerating both hard and soft sugar masses. The pulling process provides whitening and aeration of the sugar mass. It is designed to safely withdraw sugar masses within a completely enclosed space. Pulling is accomplished by pulling the candy mass on a water-cooled table with two vertical spinnerets covered with non-stick sleeves when the pull cycle begins.

Please contact us for detailed information.

Rullen (Batch Cylinder)

It is the equipment used to bring the Rullen sugar paste to the suitable rope thickness for the Rope Sizer with the help of 2 rollers on it. If desired, various filling materials can be added to the sugar paste while turning it into rope. After the sugar paste takes the form of rope to the required extent, it goes to the Rope Sizer unit.

Please contact us for detailed information.

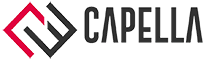

Rope Sizer ( Rope Sizer)

The rope sizer is designed to calibrate the roped sugar paste to the required size before shaping it. The resulting sugar rope is passed through 4 pairs of vertically positioned rollers. Each pair of rollers has different hole diameters and different linear speeds. This gradually transforms the sugar into sugar rope of the desired diameter and required for shaping. The sized candy rope can be given the desired shape in later shaping.

Please contact us for detailed information.

Depozitor

Depositor is a unit consisting of a compact combination of shaping and cooling units, designed to obtain a product by pouring the liquid sugar from the sugar cooking section into the molds on the machine and cooling it. The depositor can be used to produce hard candy, soft candy, filled candy, candies of one or two colors. The advantage of the sugar produced in this unit is that it is much clearer and brighter. The desired fixed weight of the product can be produced. According to the type of sugar produced, production can be made with Teflon, silicone and desired shaped molds.

Please contact us for detailed information.

Carrier Elevator

It is the unit used in product transfers, which is an important stage during production. It provides convenience in the transfer of powdered materials or small granular materials. Carrier elevators always provide the manufacturer with advantages such as fast production, time saving, low power consumption and low cost.

Please contact us for detailed information.

Packaging Machines

Packaging Machines are Fully Automatic or Semi-Automatic Packaging Systems used in almost every industry today, in the light of current conditions. These are fast, economical packaging arrangements that save significant production space. Machines with various features can be produced according to the demand of our customers or according to the product type. These machines are versatile and can be individually or multi-packed after the wide range of products has been modified and customized according to product requirements. Thanks to the equipment on these machines, which can be packaged according to the desired package type, you can minimize your time, loss and energy costs. In this way, you can provide a working environment suitable for mass production logic.

Please contact us for detailed information.

- a) Vertical Packaging Machines

- b) Horizontal Packaging Machines

- c) Double Twist and Single Twist Packaging Machines

- d) Envelope Type Packaging Machines

Conveyor Belts

It is a continuously moving equipment used to move objects from one place to another quickly and easily, without causing any damage during the production process. It facilitates efficient processes and shipping workflows in all industries. Different modular systems are required for each conveyor system to function properly and perform the tasks required by the belts. The materials used in conveyor belts can vary depending on the weight required for different tasks, the speed required and the yield of the products in the conveyor system. Choosing the right belt will increase productivity in the production process. Conveyors can be used in a variety of industries, but are extremely popular in the manufacturing and manufacturing industry as well as in the distribution and warehouse area.

Please contact us for detailed information.

Product Counters & Boxers

Product Counter and boxers is a packaging machine that counts the product, bag product or a series of products in the required number of boxes, fills them into boxes, and closes the boxes after filling. Weighing or counting of solid, powder and granular products is arranged and boxed with ultrasonic, vibrating apparatus. Our machines have been carefully designed to provide enhanced productivity, variable speed and easy pass through in any solid product packaging environment. Our counting and boxing solutions are designed to increase productivity for our customers with easy-to-use equipment that can increase output while reducing labor costs. Our manual or automatic machines; product pail loading options and box assembly offer highly consistent packaging, flexible ease of use. Our machines are designed according to the special request of our customer and according to the product to be packed.

Please contact us for detailed information.

Portable and Front-of-Machine Product Counters

It is a portable counting machine designed to accurately count soft gels, dragee chocolates or chewing gum, tablets, capsules, pills and other tableted products into jars, bottles or boxes. The counting machine with a small electronic display uses the latest high-speed counting sensors. The machine can be easily adapted to conveyor belts and line ends with product feeding system in medium to high output production facilities, and does not require part replacement. Portable product counters are capable of packing solid grain products in most tablet and capsule form. They are ideal for all kinds of automatic tablet counting applications and capsule and tablet shapes. Portable product counting machines are used in small and medium-sized companies. The count value and the number in the lot to be produced can be adjusted by the operator via the digital display. Counters, which are superior in every way to manual counting, perform precise and consistent accurate and contactless counting. Portable product counters are designed according to customer demands and requests.

Please contact us for detailed information.

Automatic Liquid Weighing-Discharging Systems

It is the equipment used in production systems that use liquid raw materials in industries. It is used as an aid to production lines in order to ensure continuity in the production process. Its automatic weighing system prevents errors that may occur because the liquids used in the formulation are weighed correctly. In this way, you can provide a working environment suitable for mass production logic in the production process. This system always provides the manufacturer with advantages such as fast production, time saving, low power consumption and low cost.

Please contact us for detailed information.

Fully Automatic Shrink Machines

Fully Automatic Shrink machines detect, seal and shrink a product without human intervention. It is widely used in production in beverage, food, medical-chemical industry. Automatic machines have infeed and output conveyors that must be loaded and unloaded as the line is processed. The pallet can perfect the packaging without cartoonish, rectangular, round or flat shape, it has the advantage of less cost and better appearance. Automatic shrink packaging machines offer the ultimate in performance and functionality and are the perfect solution for large and medium-sized companies that need a machine to integrate into the production line. An automatic shrink wrapping machine ensures a high level of results at all times. These machines have impeccable packaging quality, continuous control of temperature, processing times and packaging speed with a clear optimization of the resources used. It can automatically complete the steps of feeding, filming, closing and shrinking, and does not crease the film. POF film, PVC film and other heat shrinkable packaging can be used in automatic shrink machines. It does not require any personnel to work and has high work efficiency.

Please contact us for detailed information.

Semi-Automatic Shrink Machines

Semi-Automatic Shrink Machine is an ideal and useful machine for closing and wrapping the product with a small operator intervention. After the product to be packaged is wrapped by hand, the first gluing is done manually. After this process, the wrapped product is placed in front of the pusher manually. The machine does the rest. Settings are made in an easy and practical way.

This machine is simple in design and structure, includes pushing, sealing, cutting, packaging in one operation. The operator only needs to do a little work. This machine has the advantages of simple operation, beautiful and fast sealing, durability.

Please contact us for detailed information.

Envelope Type Shrink Machines

Envelope Type Shrink Machines are an ideal and useful machine for wrapping square, rectangular and round shaped small and medium volume products in one piece, on top of each other or in rows. Length adjustment and other mold changing settings are made easily and practically.

It packs gum boxes, candy boxes, perfume boxes, cosmetic boxes, tea boxes, tobacco boxes, medicine boxes, candy boxes and similar products in a practical way.

Please contact us for detailed information.

In-Line Feeding Systems

It is a system that serves to convey the products to the horizontal packaging machine in neat rows. This system works in harmony with other conveyor belts in the line. The main function of the in-line feeding system is to sequentially arrange the products coming from the conveyor belt for further production requirements. This system, which makes production fast and regular, provides convenience to producers in terms of production continuity.

Please contact us for detailed information.

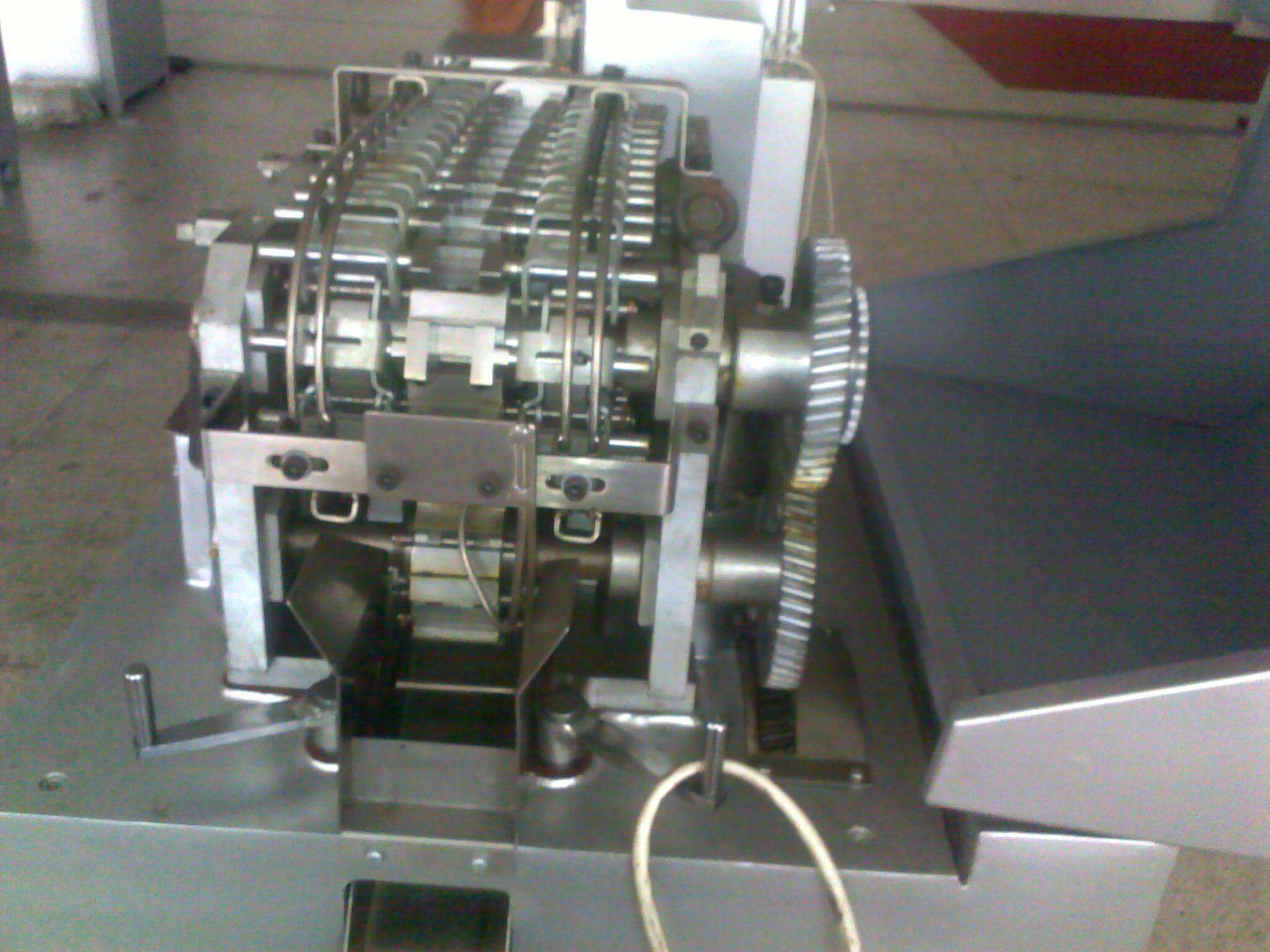

Laboratory Machines

We design and manufacture laboratory equipment used during R&D studies for production. . Machines with various features can be produced according to the demand of our customers or according to the product type. These machines can be modified and customized according to product requirements..

Please contact us for detailed information.

Second Hand Machines

We assist our customers in establishing more economical production facilities by supplying and renewing second-hand machines. We can supply and refurbish mixers, powder machines, coating drums, extruders, cooling tunnels, forming lines, packaging machines and many more food machines. Contact us for machines that can produce cost-effectively.

Please contact us for detailed information.